OUR HISTORY

In 1958 Mario Guerra, a young artisan fascinated by natural materials and intricate craftsmaship, decided to set up a workshop in Recanati, a small italian town rich in culture and ancient traditions. Thus was born A.R.C.A. Artigiana Recanatese Corno e Affini, a company specialized in the processing of Zebu horn which is molded into unique pieces.

The first creations included an extensive selection of cutlery, tableware, jewelry and personal care accessories. With just the hands and the help of fire and of a few tools, horn is shaped into timeless objects and reveals its veins that are always different by nature. Horn shades are combined with other precious materials selected with obsessive care in order to obtain exclusive pieces that make our daily gestures unique.

Over time, the founder conveyed his passion and know-how to his sons, Giorgio and Silvia. In the early 2000s the company started collaborating with designers and embraced a new path, focused in the production of complementary furniture.

In 2013, the company registered the trademark Arcahorn and mainly focused on the manufacturing of high-end furniture, while still remaining faithful to traditional craftsmanship. Each piece stands out for its impeccable quality and meticulous attention to detail and it’s conceived to enter the most elegant private residences, yachts, hotels and boutiques, also with bespoke solutions.

OUR ETHICS

Our vocation for craftsmanship is combined with the respect for the environment. We adopt low impact solutions and concentrate our production at local level. Horns we source come exclusively from free-range Zebus that are bred in compliance with the ethological habits of the animals. The species we select (Horn Bos Taurus) are not protected by the Washington convention and do not require CITES certificate. Horn acquires a new value through meticulous processes that are aimed at enhancing the organic characteristics of raw material.

ART IN THE HANDS

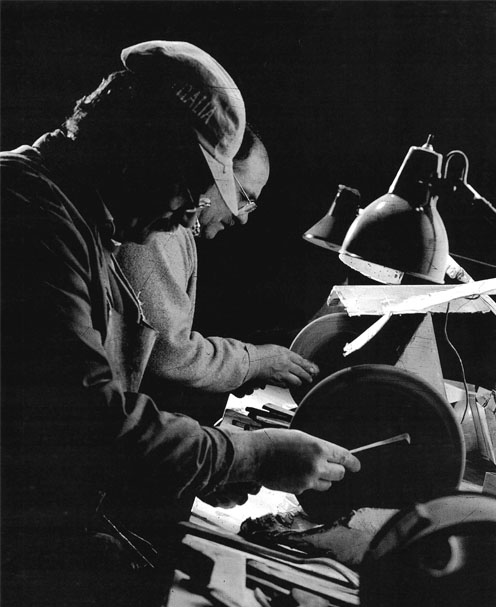

Horn shows its uniqueness only after an intricate production cycle that requires long lead times and specific manual skills. Each stage of processing is handled by skilled masters who shape horn according to ancient techniques, conveyed by tradition. After a careful selection of the best parts and their exposure to fire, horn becomes malleable and ready to be smoothed.

With the complicity of a few tools, artisans’ hands gradually turn horn into tiles to be skillfully matched together to ensure unique creations sporting infinite natural shades.